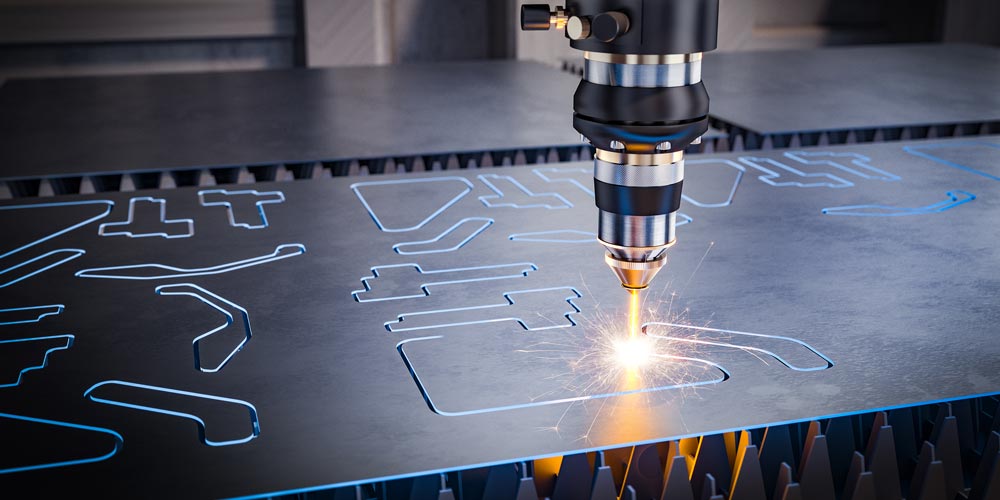

Fiber lasers are used in welding, cutting, etching, and cleaning applications. They are commonly found in material processing, manufacturing, spectroscopy, electricity, transportation, medical applications, and military sectors.

The growing manufacturing sector has led to an increased demand for these machines. Here are some ways they are revolutionizing industrial cutting and welding services in Canada.

Cost-Effectiveness

With the ability to cut through the thickest of materials, fiber laser services are highly cost-effective. This is especially true when compared to traditional metal-cutting machines.

A fiber laser’s high-intensity beam of light melts and vaporizes the material it passes through, making it possible to cut materials in various shapes and sizes with precision. The beam’s precision allows for more detailed designs, saving time and money for manufacturing.

Fiber lasers don’t require mirrors and other optical components to operate. It can reduce the overall cost of the machine as well as eliminate the need for periodic replacements and repairs. It can also save on power costs as the machine runs more efficiently. This is particularly important for large-scale productions that must be completed within a tight timeframe. It helps keep labor costs low and ensures your company meets its financial goals.

Versatility

Fiber lasers offer a versatile cutting and welding solution for shops of all sizes. This technology continually evolves toward increased precision and versatility, making it an excellent choice for metal fabrication.

The fiber laser machine can produce clean, quality cuts with minimal material waste when used correctly. This process has many benefits for industrial manufacturing, including reduced energy costs and higher efficiency.

There are two ways to operate a fiber laser: continuous wave or pulsed operation. The continuous wave operating mode allows the laser to maintain power at a constant level during the laser cutting process, which results in more consistent cuts. The pulsed operation mode focuses the light briefly, concentrating the energy more effectively.

The best way to maximize the potential of a fiber laser machine is to understand its technology and capabilities. Working with a company that can provide you with the right advice and services is essential to unlock this revolutionary machine’s full potential.

Flexibility

For fabricators looking to increase productivity, a laser cutting machine that can process multiple metal types is an attractive option. The flexibility of a fiber laser can significantly impact your business.

In the past, industrial lasers have generally been able to perform just one task effectively – either hardening or cutting metal. However, new technology allows them to do both — and even welding if required.

This kind of multi-tasking has yet to be possible with traditional systems.

It optimizes metal processing for different applications by directly tuning the laser source’s beam quality (spot size). It makes cutting many different metals of varying thicknesses and materials possible. The ability to do this quickly and efficiently means that fabrication shops can reduce downtime, increase uptime, and improve overall operational efficiency.

Safety

The most important aspect of laser cutting is ensuring that all safety protocols are followed. It includes keeping the machine clean, using a fire extinguisher when needed, and having first aid supplies nearby for any injuries. It is also essential to ensure the machine is located away from any hazards in the shop, such as water or electrical outlets.

In addition to cutting, fiber lasers are also used for cleaning metal surfaces, marking, and etching. These machines can remove paint, oxide, and rust from metals, making them ideal for applications that require tight tolerances and clean cuts.

Some industries that use continuous fiber laser cutting include the medical industry, the energy sector, and heavy machinery manufacturing. In the medical industry, the precision and cleanliness offered by fiber lasers make them ideal for cutting surgical instruments and implants. The energy industry uses these lasers to cut parts for power generation systems and renewable energy equipment. At the same time, the heavy machinery sector needs them to cut metal components for machines such as bulldozers and cranes.